Sales & Technical: 1300 66 70 71 | sales.helifix.au@leviat.com

Strategies

Helifix construction ties, fixings, repair and reinforcing systems provide secure, lasting connections in all forms of brick, blocks, concrete, stone and timber as well as traditional local building materials.

They have proven effective in virtually every type of masonry structure from medieval churches to modern tower blocks, bridges and tunnels to domestic, residential housing.

Highlighted below are problems that affect every type of commercial and residential property of all ages and construction together with strategies for repairing common faults like cracked masonry, cracked concrete, separated walls and walls suffering from failed, omitted or inadequate wall ties. Also shown are a number of reinforcing applications which may complement or form part of wider strengthening projects. Clearly there are other situations not shown here. Using appropriate combinations of Helifix ties, fixings and reinforcing rods virtually any situation can be resolved, so do not hesitate to contact us to discuss your particular problem.

Correctly diagnosing the problem

Whatever the visible structural faults, it is critical that the cause of the problem is correctly diagnosed so that appropriate repairs or strengthening procedures can be carried out. Advice should be sought from a structural engineer or suitably qualified professional who understands building movement and stresses and can devise the most effective repair or strengthening strategy with the solution tailored to suit the specific needs of the project. Whenever possible, measures to address the cause of the problem should be completed satisfactorily to mitigate the risk of on-going movement.

1. Tying walls

Remedial wall ties are installed to tie masonry leaves together or veneers to internal structural frames. Depending on construction type and site conditions, DryFix ties may be driven directly into each leaf, via a small pilot hole, to provide a completely dry connection; or ResiTie may be bonded into clearance holes to provide a resin-based fix at both ends of each installed tie; or RetroTies may be driven into a pilot hole in the remote leaf, via a clearance hole in the near leaf into which they are resin bonded.

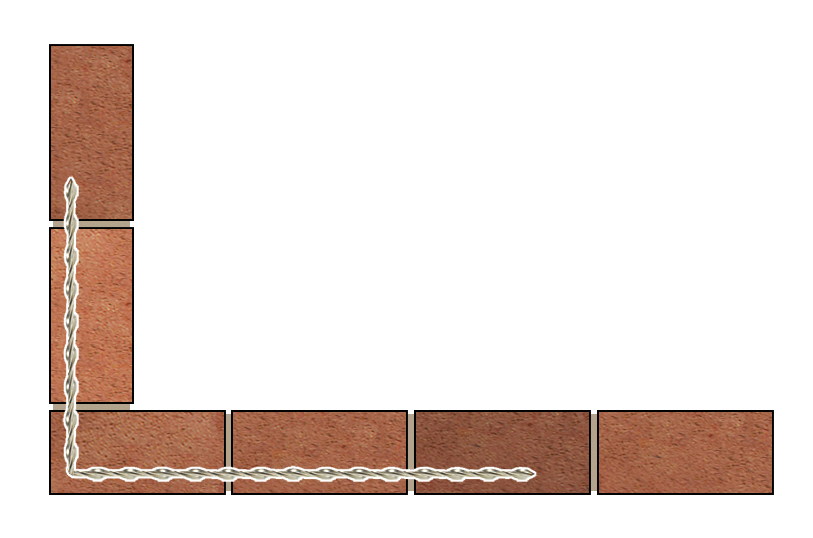

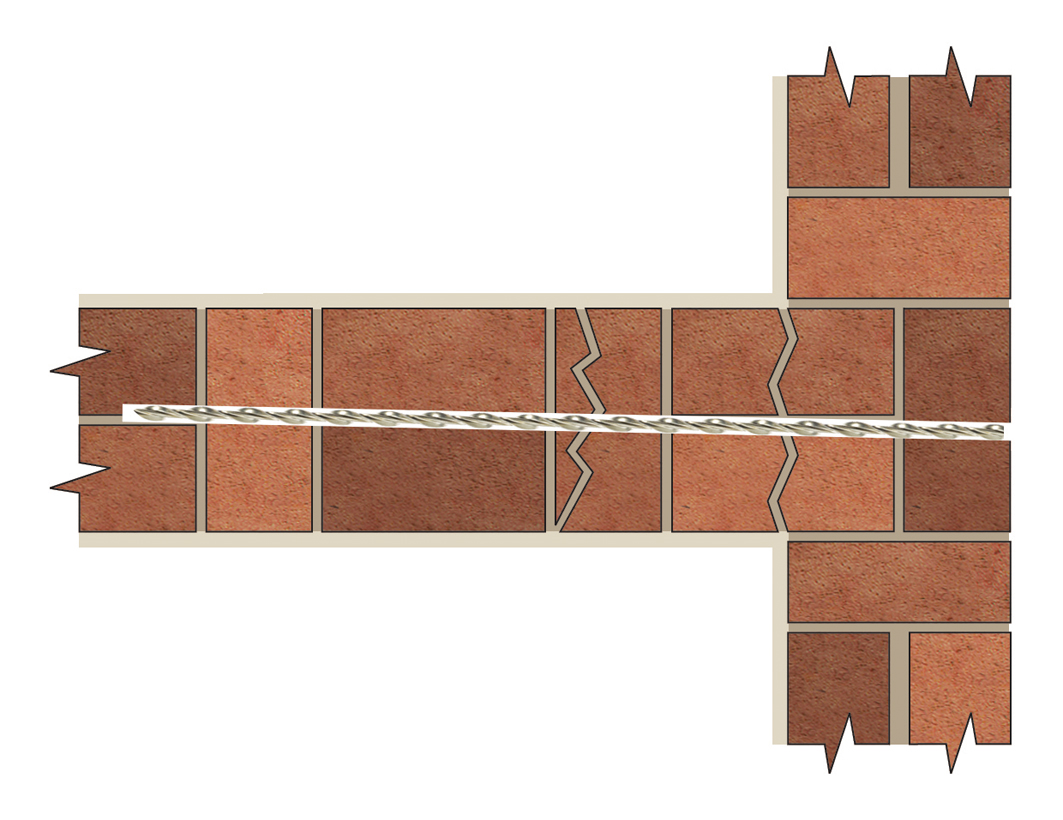

2. Tying corners

Lengths of HeliBar are bent and bonded into slots cut into the near and return wall at predetermined intervals with HeliBond grout.

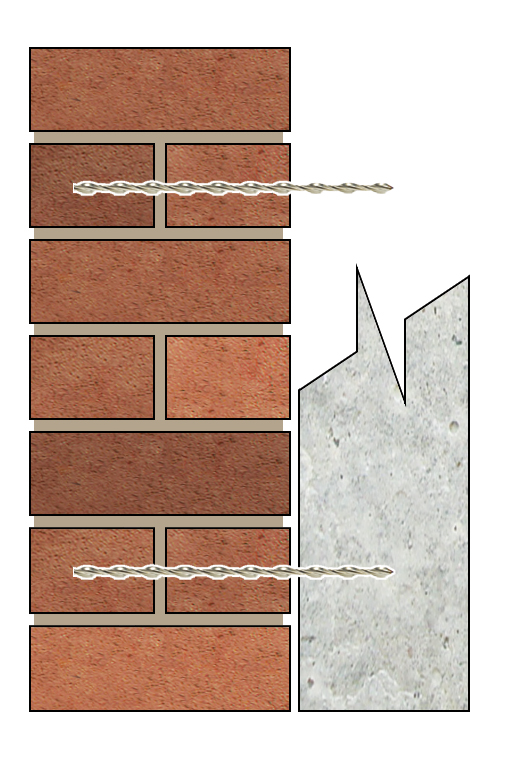

3. Tying masonry to new concrete

DryFix ties are installed directly into the wall via a small pilot hole. The tail of the tie is left exposed to be covered by the newly applied concrete.

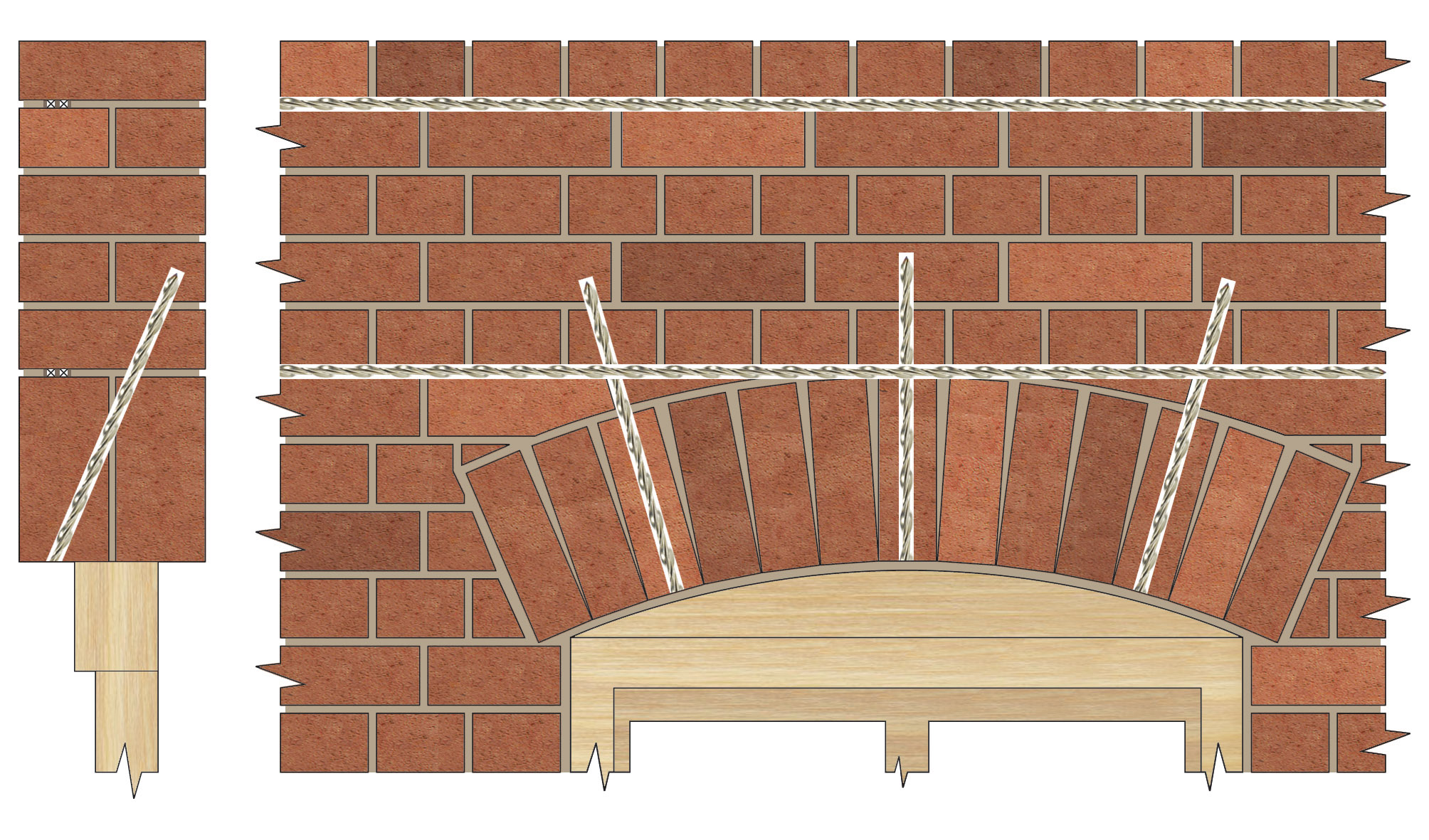

4. Repairing brick arch lintels

Parallel lengths of HeliBar reinforcement are bonded into the specified cut slots directly above the existing lintel. Angled CemTies or DryFix ties are installed through the lintel and into the masonry above the lower HeliBars.

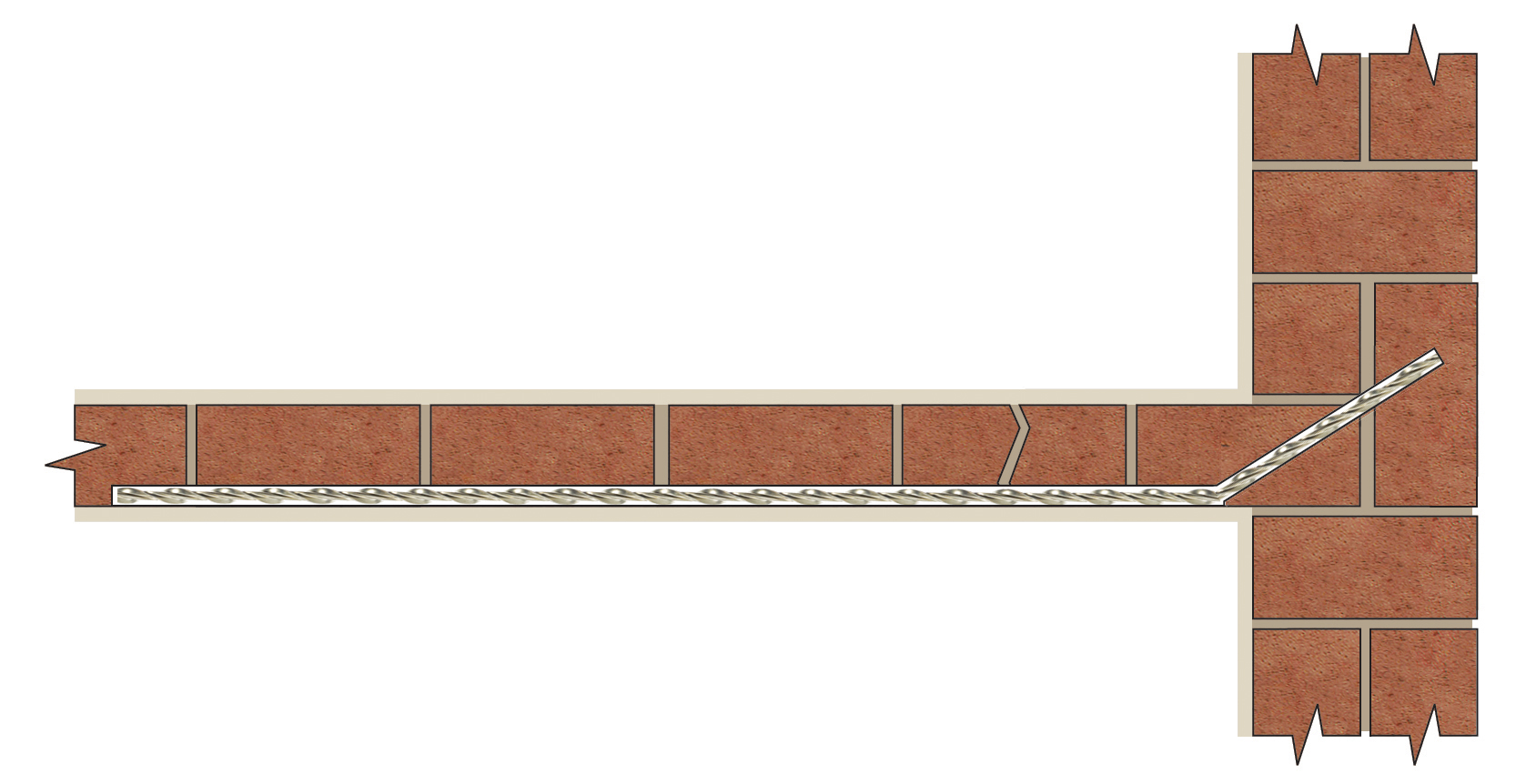

5. Tying intersecting walls

CemTies are installed simultaneously with HeliBond grout into angled clearance holes drilled through the external wall and into the internal wall to the required depth.

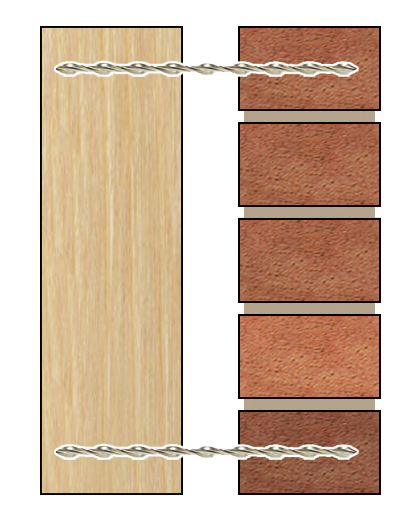

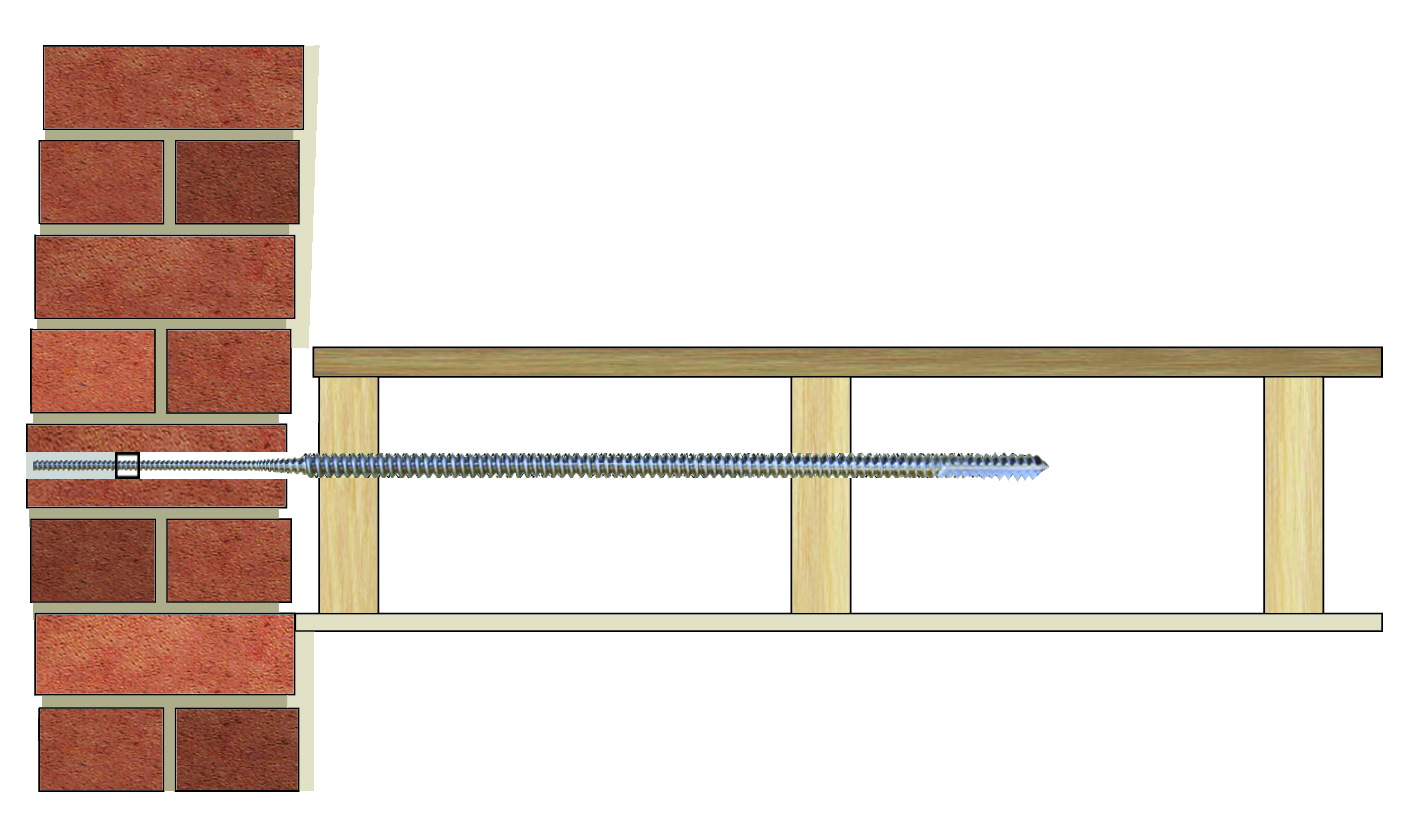

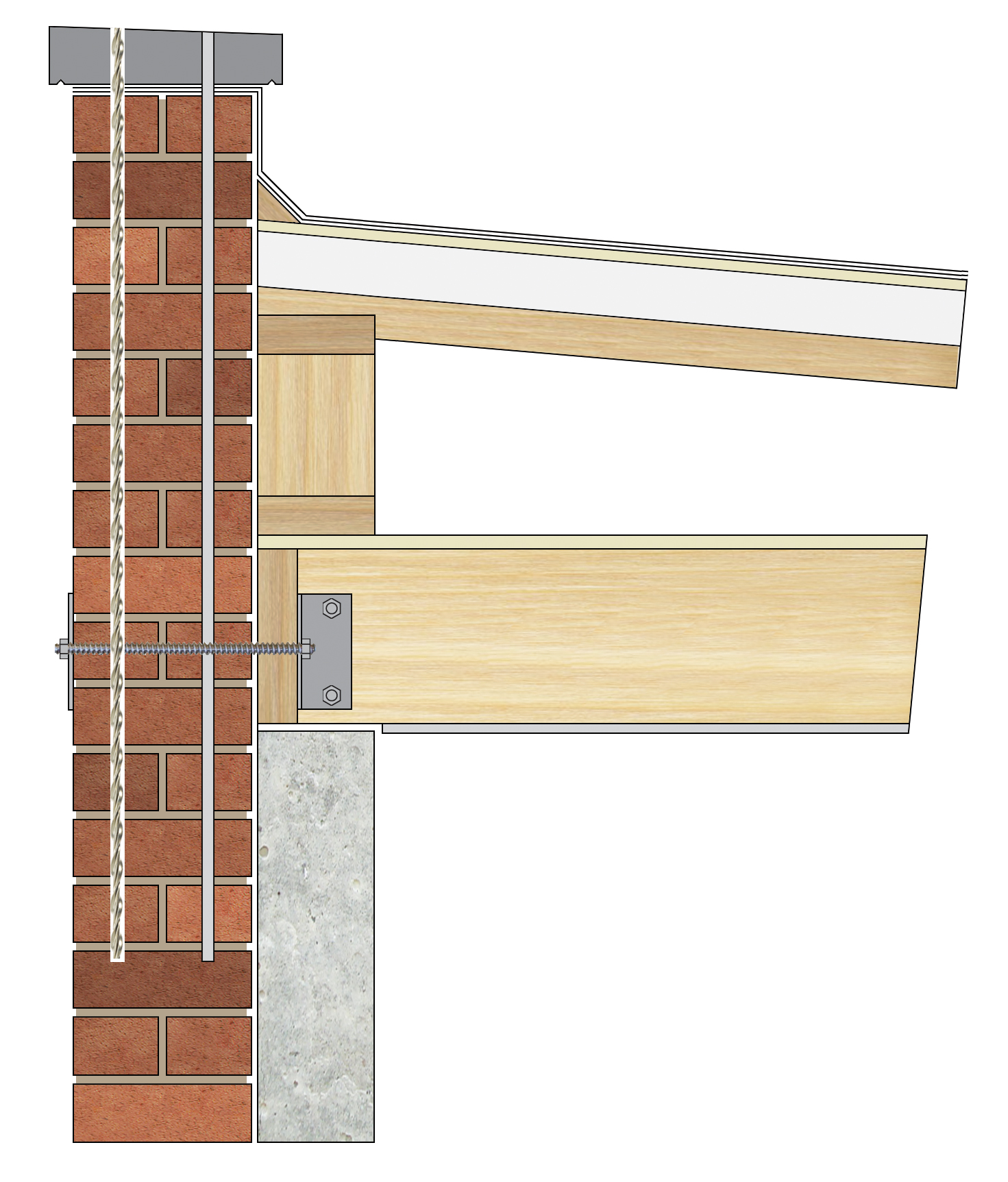

6. Tying walls to joist sides

BowTie HDs are inserted through clearance holes in the masonry and power driven through the joists leaving the outer end to be bonded into the masonry with EpoxyPlus TE resin.

7. Pinning multi-leaf masonry

DryFix ties or CemTies, depending on requirements, are installed directly into the brick leaves. DryFix ties are power driven directly into the wall, via a small pilot hole, typically 5mm in diameter, while CemTies and HeliBond grout are installed into clearance holes drilled through the near leaf and into the far leaf. The density of the ties, DryFix or CemTie, will depend upon the degree of separation, the material, the cause and the condition of the masonry overall.

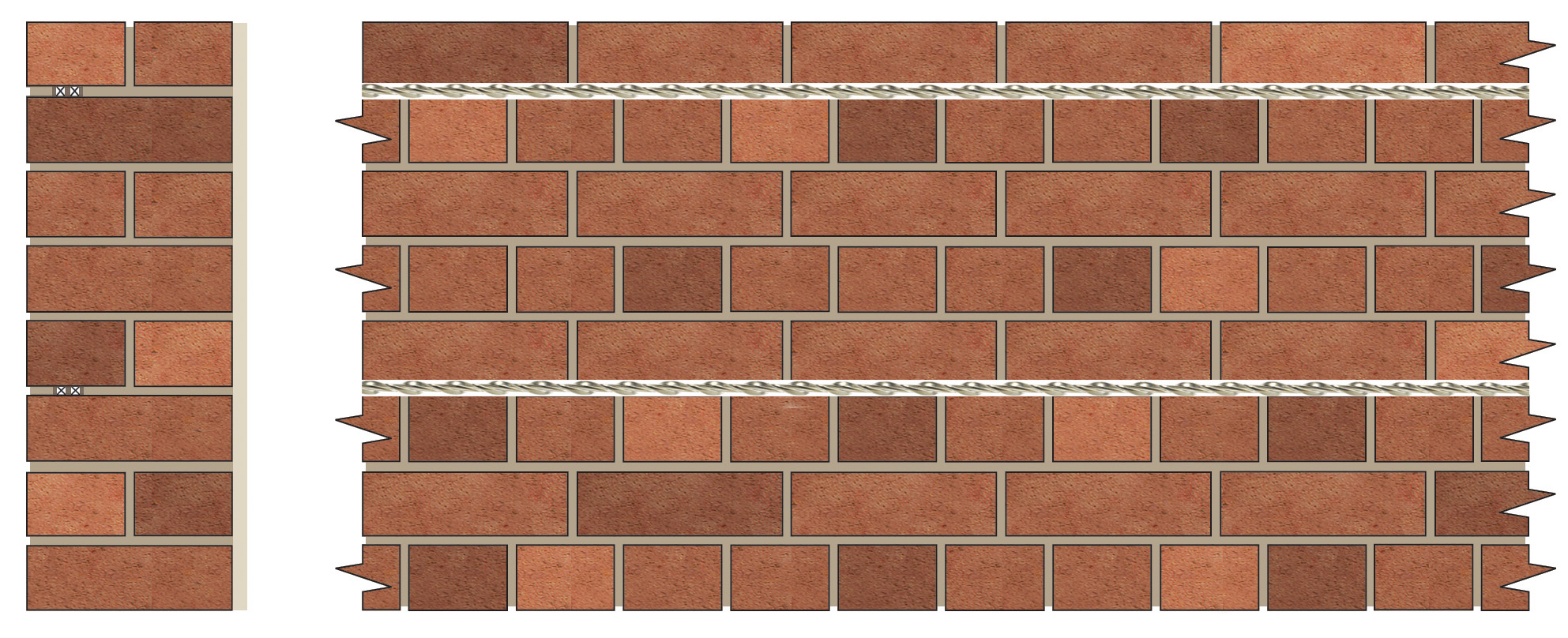

8. Creating masonry beams

Parallel lengths of HeliBar reinforcing are bonded into predetermined cut slots (normally cut into the mortar beds) using HeliBond grout to form deep masonry beams which distribute the building loads. Helibeams may be used to resist both vertical and lateral loads.

9. Concrete Crack Injection

CrackFix resin is injected directly into the crack via injection ports that are affixed to the wall. The ports are mechanically removed from the wall once the resin has cured.

10. Parapet repairs

CemTies are installed simultaneously with HeliBond grout into clearance holes drilled down into the wall to the required depth. Parallel lengths of HeliBar reinforcing are bonded into predetermined cut slots (normally cut into the mortar beds) with HeliBond grout to tie the masonry together and form masonry beams. DryFix ties and BowTies are installed wherever possible to tie the masonry to joists and timber frames to complement and further reinforce any other lateral restraint systems used.

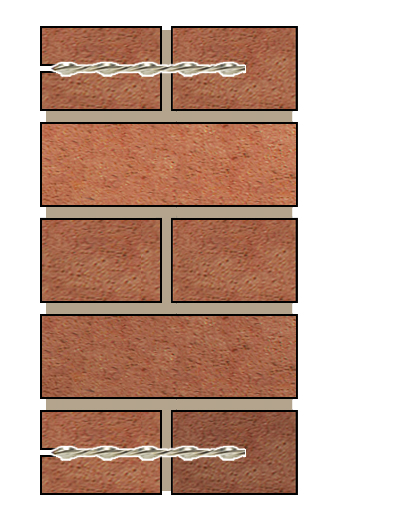

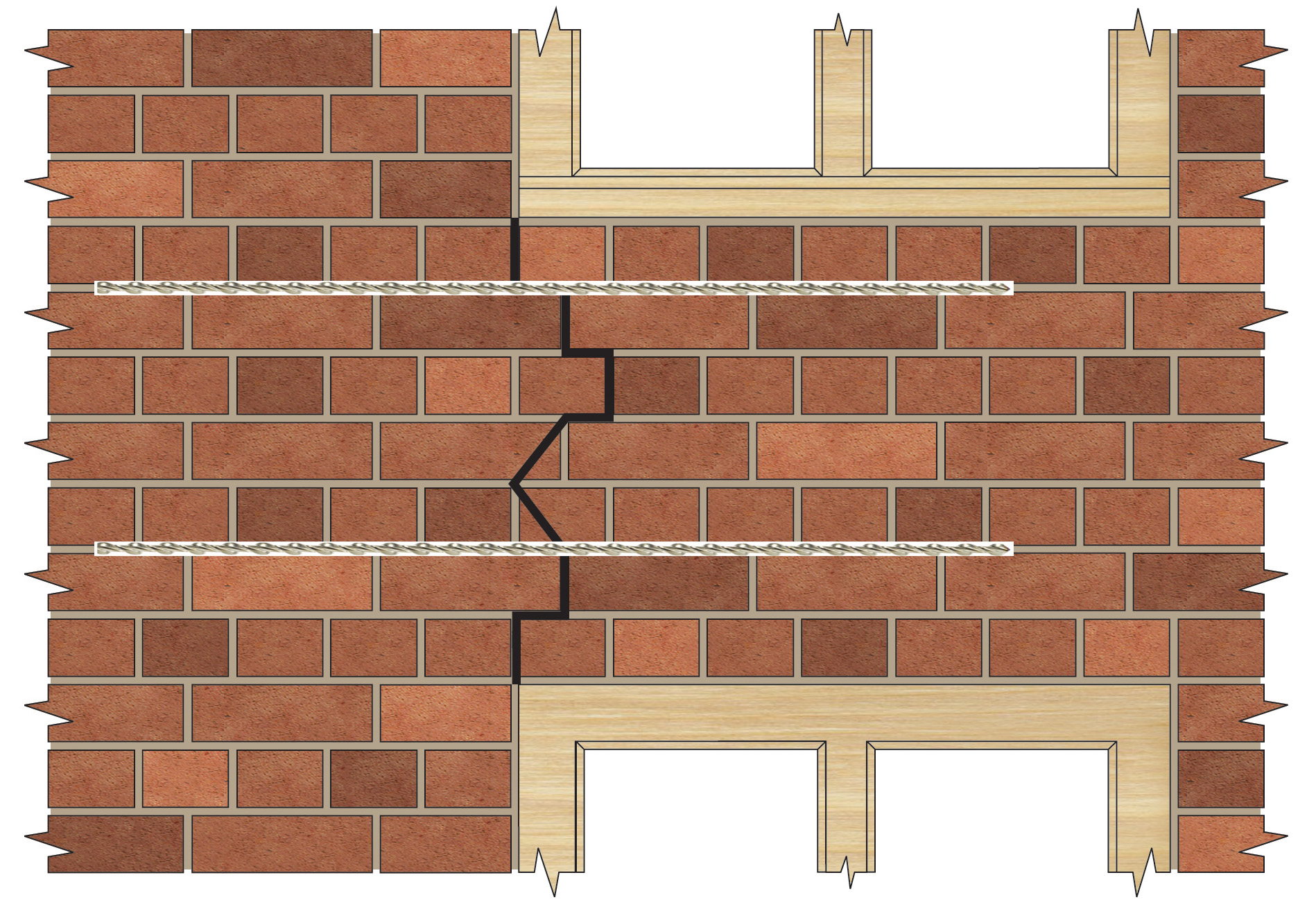

11. Crack Stitching

Lengths of HeliBar extending 500mm either side of the crack are bonded into slots normally cut into the mortar beds, using HeliBond grout. Where cracks are less than 500mm from an external corner or an opening, at least 100mm of HeliBar should be bent round the corner and bonded into the return wall or bent and fixed into the reveal, avoiding any DPC membrane.

12. Reconnecting walls

Predetermined slots on the internal wall are channelled out to the specified length and depth right into the corner. Angled holes of 10mm diameter are drilled from the corner into the external wall. Single lengths of HeliBar are bent to shape, with the angled end bonded into the hole with EpoxyPlus TE resin or HeliBond grout and the remainder grouted into the internal wall using HeliBond grout.